Online forms in industry: productivity, traceability, and instant data

In today’s industrial landscape, marked by the constant search for greater efficiency, regulatory compliance and traceability, online forms in industry are emerging as an essential tool. It is not just about replacing paper, but revolutionizing how operational information is collected, shared and analyzed from the field to the back office.

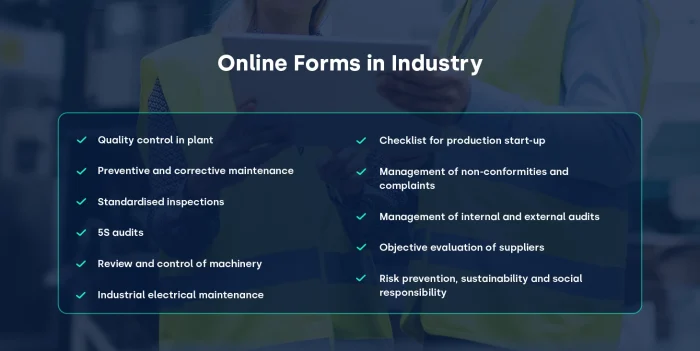

Whether for quality control, maintenance management, occupational safety or supplier evaluation, online forms allow you to connect teams, automate processes and improve decision making in real time.

Adopting online forms not only involves digitizing processes, but also optimizing resources and increasing operational agility.

Thanks to them, data capture is performed directly from the field, with automatic validation, instant availability and direct connection to management platforms such as ERPs, GMAOs or BI systems.

Let’s look at some of the areas where online forms for industry are already making a tangible impact:

Structured inspections, with data recording, images, observations and signatures, all in real time. Facilitate early detection of non-conformities, follow-up of corrective actions and automatic report generation.

With online forms, technicians can document each intervention, attach images, schedule upcoming inspections and sign digitally. This generates a history useful for analyzing failures and improving asset availability.

Inspection protocols are digitized with customized forms for each piece of equipment or area, ensuring compliance, facilitating audits and improving data quality.

Online forms can be used to perform 5S audits in a structured manner, identify deviations, record evidence and foster a culture of continuous improvement.

The digitization of industrial maintenance with online forms makes it possible to record inspections, plan maintenance and proactively detect possible faults from any location.

Online forms allow you to document tests, inspections, corrections and results. They contribute to more effective planning and increase electrical safety in the plant.

Verifying that everything is in order before starting production is essential. These forms allow you to record each verification step by step, preventing errors and optimizing start-up times.

Incidents can be recorded from the field with images, observations and automatic categorization. In addition, it is possible to assign responsible parties, launch corrective actions and follow up with full traceability.

Online forms make it possible to organize audits, collect evidence, record results and reduce the effort of preparation and subsequent analysis.

Periodic evaluation can be standardized with forms tailored to quality, delivery or sustainability criteria. This improves traceability and facilitates decision making based on real data.

From occupational risk prevention (ORP) to corporate social responsibility (CSR) to health, safety and environment (HSE), the forms allow you to document inspections, incidents, audits, environmental assessments and more. Thus, they help to comply with legal and international standards.

Implementing online forms in industries is more affordable than it sounds. Here are the key steps:

In industries where every mistake has a high cost and agility makes the difference, online forms in the industry are not an option, but a competitive advantage.

In this sense, FIELDEAS Forms offers a comprehensive, robust and accessible solution for the digitization of industrial processes. From the recording of data in the plant to its analysis in real time, it allows to connect operations in a safe and efficient way.

Making the leap to digitalization with online forms means gaining in efficiency, traceability, security and sustainability.

13 Feb 2025

Digital versus paper forms: which is better for your company?

29 May 2025

Online forms in utilities: use cases and main benefits

16 Jun 2025

Online forms in construction: efficient, secure and collaborative digitization

18 Jun 2025

Online forms in retail: key solution for efficient, customer-centric management