These are the benefits of integrating a YMS according to shippers companies

We have already talked on several occasions about the main benefits of a YMS (Yard Management System), among which are the reduction of waiting times, increased productivity, optimization of storage space or cost reduction, among others.

On this occasion, we are going to talk about the benefits of integrating a YMS that the shippers companies themselves that already have a dock management digitization solution have experienced.

This has been reflected in the study “Dock Management in Spain three years after RDL 3/2022: Degree of digitalization and perspectives of shippers and carriers”, prepared by FIELDEAS and the Spanish Logistics Center (CEL).

As reflected in one of the main conclusions of the study, 51.16% of the shippers companies already have a technological solution for dock management or YMS.

Specifically, of this total, 34.88% have adopted third-party software, while 16.28% have developed and implemented their own system.

Among the loading companies that have incorporated digital tools to manage their loading and unloading operations, the majority (59.10%) indicate that these solutions are used in both inbound and outbound processes, which is evidence of a commitment to optimize the entire dock activity in an integrated manner.

On the other hand, 22.70% have focused their digitization only on the outbound flow, with the aim of improving dispatch and outbound coordination, while the remaining 18.20% have focused their efforts on the inbound area, directing the improvement towards product reception and inbound management.

While the digitization of dock management still presents significant challenges, it also brings real benefits that outweigh the theory.

Thus, the application of technological solutions in the loading and unloading processes has generated significant improvements in different operational aspects for loading companies.

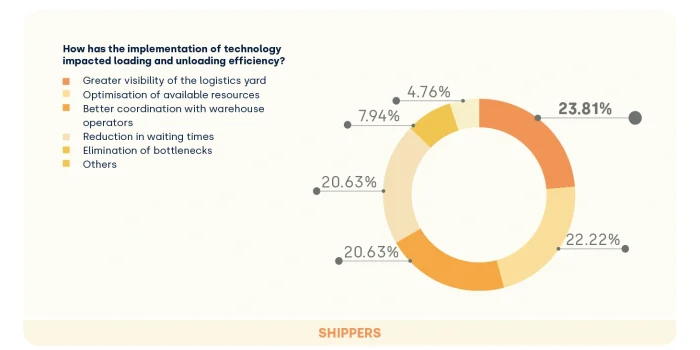

When asked how the implementation of technology has impacted the efficiency of loading and unloading, the shippers companies highlighted the improvement in the visibility of the logistics yard with 23.81%, as it facilitates the control and management of traffic and spaces.

The Layout or Platform Manager functionality of the FIELDEAS Track and Trace YMS provides complete, real-time visibility of the logistics yard.

Thanks to this visual layer, yard management is transformed into a much smoother, more accurate and easier to monitor operation, even in complex logistics environments with multiple control points.

In addition, this increased visibility leads to improved relations between the various stakeholders, thanks to real-time information.

Another of the benefits most valued by the loading companies when integrating a Yard Management System is the optimization of available resources, pointed out by 22.22% of the companies.

This type of solution maximizes the use of physical, human and time resources involved in loading and unloading operations.

Thanks to the real-time visibility provided by a YMS, companies can allocate docks more efficiently, reduce downtime and better coordinate the arrival and departure of vehicles. In addition, the automation of tasks and digitization of information avoids overstaffing or underutilization of facilities.

Implementing a YMS has also enabled many loading companies to achieve better coordination with warehouse operators, a benefit noted by 20.63% of companies.

By digitizing dock management, continuous communication between loading and unloading personnel, warehouse managers and carriers is encouraged, contributing to a more synchronized and efficient operation.

Thanks to the real-time information provided by a solution such as the FIELDEAS Track and Trace Dock Management module, teams can know precisely the real situation of the activity, avoiding delays and reducing errors due to lack of coordination.

Overall, this improvement in internal communication boosts productivity, reinforces operational safety and consolidates a more agile and collaborative management throughout the logistics environment.

Reduced waiting times, mentioned by 20.63% of the loading companies, is another key benefit of implementing a Dock Management solution.

A YMS makes it possible to manage the arrival and departure of vehicles with greater precision, avoiding congestion at the docks and improving the flow of internal traffic.

By having up-to-date information on the status of each dock and available time slots, companies can proactively plan loading and unloading operations.

This translates into shorter waiting times for carriers, faster vehicle turnover and more efficient utilization of warehouse resources.

In addition, the reduction of waiting times not only increases productivity, but also has a positive impact on driver and operator satisfaction, reducing operational pressure.

The elimination of bottlenecks, highlighted by 7.94% of the loading companies, is another tangible result of implementing a YMS.

By providing a complete, real-time view of the flow of vehicles, docks and operations, this type of system enables congestion points to be detected quickly and acted upon before they affect overall performance.

Through task automation, intelligent dock assignment and dynamic scheduling, YMS helps maintain a constant and balanced flow of operations, avoiding unnecessary backlogs and downtime.

As a result, companies achieve greater operational continuity, reduce delays in loading and unloading and improve coordination between the different teams involved.

Another benefit mentioned by shippers is improved security, both in terms of work and data protection.

On the operational side, a YMS allows precise control of the movement of vehicles and personnel on the docks, avoiding accidents, conflicts and damage to goods or equipment.

Route planning, space allocation and task coordination ensure a safer and more organized work environment for operators and carriers.

At the same time, a YMS such as FIELDEAS Track and Trace ensures the protection of operational data, centralizing information on loads, schedules, resources and operation records in a secure digital platform.

This prevents loss of information, human error and unauthorized access, strengthening the integrity of logistics processes and decision making based on reliable data.

Overall, the integration of a YMS provides a safer, more efficient and reliable environment, where physical risk prevention and information security work hand in hand to improve daily operations and protect both people and the business.

We have already seen what the main benefits mentioned by loading companies are, but it is important to underline the importance of having a dock management solution or YMS that guarantees their materialization.

In this sense, the Yard Management System or dock management module of FIELDEAS Track and Trace, supply chain visibility platform, is designed to adapt to any infrastructure, type of operation and level of digital maturity of the logistics center or warehouse.

Based on flexibility, collaboration and transparency, FIELDEAS Track and Trace YMS guarantees efficiency, control and total visibility in dock management.

01 Oct 2025

Dock Management 2025 Study: 51.16% of shippers already have technological solutions in place

08 Oct 2025

One dock, two realities, one solution: dock digitization

16 Oct 2025

What do shippers and carriers think of RDL 3/2022?

23 Oct 2025

Digitization challenges in dock management according to shippers and carriers