Measuring to improve: why your digital form needs KPIs

In the current business scenario, where efficiency and traceability are key to competitiveness, the digital form has become an essential resource for capturing, organizing and analyzing data in real time.

Even so, many companies continue to use it only as a substitute for paper, without taking advantage of its true value: the ability to measure their performance through KPIs (Key Performance Indicators).

Evaluating the effectiveness of digital forms is what distinguishes simple digitization from true data-driven operational optimization.

In this article we look at why KPIs are key to digital forms and how they drive efficiency, quality and decision making in industrial and service environments.

The digital form is not just an interface for recording information. In industries such as maintenance, inspection, logistics, quality control or automotive, each form represents a source of field data that reflects the actual status of operations.

Without indicators to measure the data collection process, this information loses some of its value. Companies collect thousands of records daily, but if they do not analyze how, when and with what level of efficiency they are generated, it is impossible to detect delays, failures or opportunities for improvement.

That’s why KPIs are the next logical step in a digital maturity strategy: they allow you to turn data input into operational intelligence.

It is not about measuring for the sake of measuring. KPIs should support key business objectives: efficiency, quality, compliance and user experience.

Thus, a digital form allows you to visualize these objectives through reports and dashboards that identify trends and patterns, but it is also essential that it incorporates internal metrics such as completion rate, registration times, errors detected, productivity and approval times.

This step is essential when implementing a digital forms solution for the first time, as it allows to evaluate processes and improve the performance of the teams in the field.

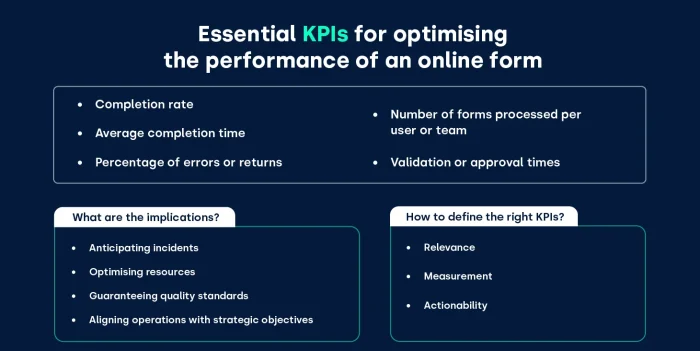

The following are some of the most relevant indicators:

Measures the percentage of completed forms versus initiated forms. A low rate usually reflects forms that are too long or unintuitive, or technical difficulties.

Optimizing usability and simplifying design often results in significant improvements.

In operational processes where technicians must record information in the field, time spent is critical.

This KPI helps to evaluate efficiency, identify unnecessary steps and improve operational cycles.

A high number of rejected or corrected forms may indicate a lack of automatic validations, interface problems or poor flow.

A good digital forms system should include automatic controls that reduce these failures at the source.

It allows analyzing individual and group productivity, identifying more efficient teams and detecting imbalances in the workload.

In processes where forms require review (e.g., intervention parts or safety reports), this KPI measures the time between submission and final approval. Reducing it translates into greater operational agility.

Tracking KPIs in digital forms provides real-time visibility into the health of processes.

In this sense, organizations that adopt this approach achieve:

The use of KPIs requires systems capable of automatically collecting, processing and analyzing information.

Thus, platforms such as FIELDEAS Forms centralize all data captured in the field, integrate them with corporate systems and generate visual dashboards to monitor key indicators such as operating times, productivity or efficiency of technical personnel.

On the other hand, flow automation reduces manual errors and speeds up information management.

In this way, the result is an intelligent digital ecosystem, where each digital form not only records information, but also actively contributes to continuous improvement.

There is no standard set of KPIs valid for all companies. Their design should be based on three fundamental principles:

Therefore, a good initial practice is to start with critical indicators (such as registration time and error rate) and expand as the use of the digital form evolves.

The objective is to create a cycle of continuous improvement based on quantitative evidence.

The implementation of a digital form should not be the ultimate goal, but a means to gain control and visibility over processes.

KPIs allow you to turn data capture into a competitive advantage, improving productivity, quality and compliance.

With FIELDEAS Forms, companies can define, monitor and analyze metrics that really add value, supporting data-driven management. Because what cannot be measured, cannot be optimized.

FIELDEAS Forms online forms software has a drag & drop editor, which facilitates the design of customized or template-based forms, adapted to different use cases such as inspections, checklists or inventories, among others.

In this way, once the performance KPIs of the technical team have been analyzed, it allows us to adjust the forms in an agile and simple way to boost productivity and the flow of data collection in the field.

The main capabilities of FIELDEAS Forms are:

Thanks to all this, FIELDEAS Forms offers a comprehensive solution to implement a digital form that drives efficiency, traceability and analytics in any organization.

10 Oct 2025

Practical guide to integrate online forms in your company

17 Oct 2025

How to strengthen data security with digital forms

24 Oct 2025

Benefits of using FIELDEAS Forms digital forms software

31 Oct 2025

How digital forms drive sustainability in industry