How digital forms in manufacturing processes help you collect, manage and analyze data

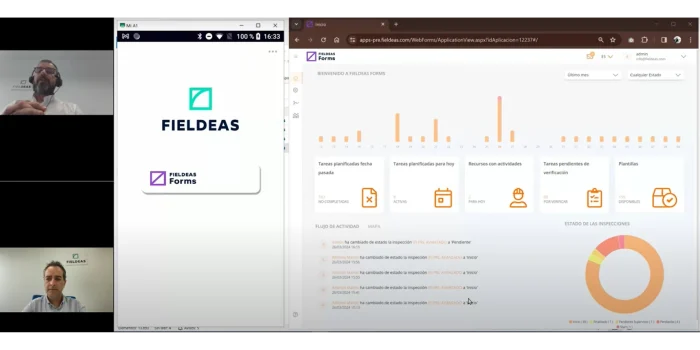

Webinar "Digital form integrated in the product life cycle in manufacturing"

The integration of digital forms into manufacturing processes brings a wide range of benefits to the industry by digitalization the collection, management and analysis of data in the life cycle of a product.

In this sense, and with the aim of showing all the competitive advantages of this type of tools, FIELDEAS Forms has held the webinar “The digital form integrated into the product lifecycle in manufacturing.”where our experts have shown how to implement digital forms in a simple, flexible and accessible way.

A digital form is an electronic version of a traditional paper form, whose data collection is done through digital tools.

In this way, digital forms facilitate the collection, management and analysis of data, crucial elements for developments, launches, marketing or continuous improvement of products within a company.

In addition, digital forms are very versatile tools because they have a lot of flexibility and can be used in a variety of ways. use at any stage of the life cycle of a product being manufacturedThe company’s products and services range from the initial phases of design, prototyping or raw material sourcing, to the final phase, after-sales, analysis of results and satisfaction surveys of end customers.

Thus, the integration of FIELDEAS Forms digital forms in the life cycle of a product brings with it:

The industry in general is accustomed to the use of paper for data collection in the field. However, not implementing digital forms in manufacturing processes has disadvantages such as:

On the other hand, using FIELDEAS Forms digital forms in the manufacturing processes brings multiple advantages such as:

During the webinar, our experts explained each of the areas in which FIELDEAS Forms can intervene in the life cycle of a product in manufacturing.

In logistics activities, FIELDEAS Forms digital forms can optimize the checking of access to the plant by carriers, the verification of documentation of orders arriving at the plant and the receipt of raw materials.

In maintenance activities, the digital forms facilitate inspections of installations with preventive or corrective work and allow for reviews of fire protection equipment, among others.

In the field of safety, digital forms can be used in Occupational Risk Prevention (ORP) or in surveillance rounds.

On the other hand, digital forms optimize the Total Productive Maintenance (TPM) process, which involves the maintenance and production departments.

Digital forms facilitate product inspections, such as assays, tests… When the raw material arrives at the plant, for example, samples can be taken and labeled so that the laboratory team can perform their analysis and determine the results.

With the digital forms it is possible to keep an exhaustive control of the placement of the products in the warehouses and to carry out the inventory of finished product and of materials and spare parts.

At the time of transport, the digital forms allow checking the product loading on the truck, picking references per order and checking the vehicle status.

In the customer service area, digital forms can be used to conduct satisfaction surveys, manage incidents and verify the quality of the delivered product.

There are many tools on the market that allow you to digitize forms, but FIELDEAS Forms has integration in its DNA.

As our experts explain, we do not enter companies to replace corporate systems, but we position ourselves as a transversal layer to all the systems that are used on a daily basis.

Thus, the main features of FIELDEAS Forms digital forms are:

In addition, digital forms in FIELDEAS Forms manufacturing processes have a number of great added values:

FIELDEAS Forms is an integrative tool, we not only replace paper or office automation tools for data collection, but we integrate with layers of IoT, ERP, MES, CMMS, CMMS or PLM, among others thanks to our APIs.

In addition, we do this integration in a bidirectional way, so that we can capture data from these systems and return them with the results of the executions.

All of the above derives in a conclusion and a main advantage, the reduction of Time to Market. The implementation of digital forms in the production process of a company is a matter of days and, once implemented, the process of control of the production process is a matter of days. is expeditedThis allows the product to be on the market in a shorter period of time than when using paper forms.

Thus, the integration of digital forms in the life cycle of the product in manufacturing involves:

If you want to see how FIELDEAS Forms digital forms work and how they can help you to optimize the life cycle of a product in manufacturing, do not hesitate to request your demo and our experts will show you all its advantages.

29 Jan 2026

Frequently asked questions (FAQs) on road transport documents

Numerous road transport documents are used in day-to-day road freight transport: control document, consignment note, CMR, delivery note, stowage form, waybill… All of road transport documents are relevant, but not…

23 Jan 2026

No-code electronic form: efficiency for companies with field operations

For companies operating in the field, achieving high levels of efficiency and competitiveness is an additional challenge, as digitizing processes becomes even more relevant. In this scenario, the electronic form…

22 Jan 2026

Comprehensive digitization of road transport documents: mandatory vs. strategy

The management of road transport documents is going through a key moment. The arrival of the mandatory digitization of the Control Document in October 2026 opens the door to the…

15 Jan 2026

How does the digitalization of the control document affect drivers?

The imminent entry into force of the mandatory digitalization of the control document has led to a flood of doubts and questions that are gradually being resolved. We always talk…