How to ensure the integration of online forms with other business systems

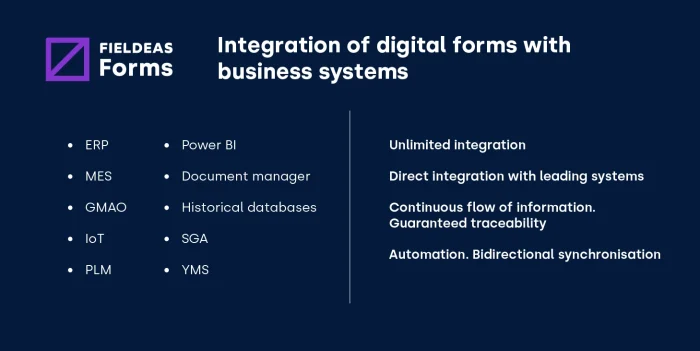

Implementing digital forms without the ability to connect them with other enterprise systems limits their true value. Therefore, ensuring the integration of online forms with platforms such as ERP, MES, CMMS, IoT, document managers or Power BI is essential to maximize their usefulness.

Digital forms not only replace paper, but represent the gateway to operational data that drive decisions, automate processes and feed central management systems.

Their true value, therefore, comes when they are integrated with key business solutions. In this post we analyze how the integration of online forms with different systems transforms the operation, control and process improvement of organizations.

Capturing data through forms is only the first step. The real potential comes in what happens next:

Without integration, data remains isolated. With integration, it becomes operational information in real time, impacting the entire organization.

Connecting the digital forms with the ERP allows the information collected in the field or plant to automatically feed processes such as: orders, receipts, work reports, time allocations or material consumption.

Benefits of this integration:

Practical example: A technician completes an intervention form and the work report is automatically generated in the ERP. The project costs are updated and the invoice is sent to the customer without manual intervention.

In industrial environments, digital forms connected to the MES allow to capture:

This provides an immediate view of the plant and speeds up the execution of tasks.

Practical example: An operator reports a breakdown or shortage during production using a digital form. The information is instantly reflected in the MES, allowing the supervisor to act without waiting for the shift to close.

The integration with CMMS allows:

With the combination of IoT and forms, predictive maintenance chains can be set up based on real conditions.

Practical example: A technician detects a failure and reports it through a digital form with photos and priority. A warning is automatically generated in the CMMS and, after the intervention, the asset history and maintenance performance is updated.

Integrating digital forms with IoT allows:

Practical example: A sensor detects a temperature rise on a machine and alerts the operator. The operator completes the digital form with the actions taken, such as slowing down or stopping the machine.

In companies with product development, connecting digital forms with PLM makes it easier:

Practical example: An operator completes a digital form after inspecting a new batch. The data is automatically sent to the PLM, providing feedback to engineering and closing the product improvement cycle.

A robust integration with Power BI allows:

Practical example: Production and maintenance data are automatically synchronized with Power BI, generating dashboards that allow monitoring KPIs such as production times, incidents or rejection rates.

All digital forms must be integrated with the corporate document system:

Practical example: A digital inspection form is automatically saved in the document manager, linked to the corresponding work order. This ensures traceability and quick access to information.

The integration of digital forms with existing databases avoids duplication and reinforces data consistency. Allows:

Practical example: Before sending a quality form, the system validates batch and product against the database. The form is automatically stored, updating the quality history.

Integrating digital forms with the WMS allows:

Practical example: An operator registers a receipt using a digital form. The data is synchronized with WMS, ERP and document manager, ensuring updated inventory and traceability.

In logistics yards, integration allows:

Practical example: Safety inspections and yard status are recorded via digital form and automatically integrated with the YMS, optimizing planning and follow-up.

For integration to be sustainable, the forms solution must offer:

In addition, it is essential to have a technical team that understands the customer’s processes and manages the integration with agility.

Here is the post How to integrate digital forms in your company?

The integration of online forms is not an extra, but a strategic requirement. Only a solution like FIELDEAS Forms is able to connect with all the company’s systems and automate flows, improve efficiency, reduce errors and increase operational control.

FIELDEAS Forms connects natively with ERP, CRM, BI, GIS or IoT, adapting to diverse ecosystems.

Easily integrate with SAP, Power BI, Salesforce and any application via APIs or standard connectors.

Data flows seamlessly between field and office, ensuring traceability and consistency, simplifying decision making.

Processes are automated, eliminating duplication and speeding up decisions. With FIELDEAS Forms, data flows without worries, improving daily efficiency.

13 Feb 2025

Digital versus paper forms: which is better for your company?

12 Sep 2025

Digital forms in automotive: digitization of processes and added value in the industry

18 Sep 2025

Online forms in inspections and certifications: the key to optimize business management

14 Nov 2025

Smart and collaborative forms: optimize your business efficiency