Intelligent docks programming: logistics management in real time

Efficient management of loading and unloading docks has become a critical factor in the supply chain. In an environment where timeliness, operational agility and resource optimization make the competitive difference, intelligent docks programming emerges as an essential tool to improve logistics performance.

In this post we analyze how digitization, the use of real-time data and process automation are transforming the way companies schedule and allocate their docks. A practice that can no longer rely on spreadsheets or phone calls.

Loading and unloading docks are no longer a simple transit point: they are a critical coordination node between multiple stakeholders (carriers, shippers, logistics operators and warehouse personnel), goods and information.

Thus, when spring reserve scheduling is inefficient, the consequences are clear:

With increasing pressure to reduce time and costs, dock management needs to evolve to an automated, dynamic and connected model.

Traditionally, dock planning was based on fixed time slots allocated in advance, with little or no capacity to react to unforeseen events.

However, today’s logistics environment demands constant adaptability. En-route delays, last-minute load changes or operational contingencies make rigid planning obsolete from minute one.

As a result, more and more companies are migrating to a dynamic, real-time scheduling model, where loading and unloading slots are automatically allocated or adjusted based on:

This approach reduces waiting times, optimizes the use of resources and allows a much more fluid and predictive management.

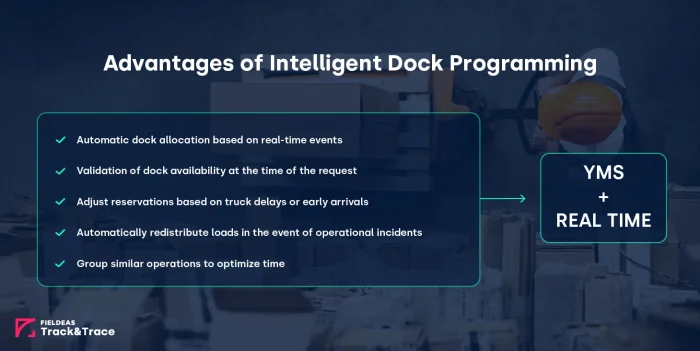

Intelligent dock assignment is not just about automating reservations. It is a data-driven system that makes optimal decisions in real time. These solutions, integrated within Yard Management System (YMS) platforms, use algorithms to:

In addition, these platforms enable direct interaction between carriers and warehouses, allowing drivers to self-manage their appointments, confirm arrivals or receive instructions directly on their cell phones.

The positive impacts of good scheduling are manifold and affect the entire transport chain:

Dynamic dock reassignment and continuous updates on the status of operations minimize truck downtime.

By having visibility of the status of each dock in real time, overloading of logistic zones or schedule collisions are avoided.

Efficient scheduling, based on real-time data, allows the carrier to perform its operation quickly, accurately and without unnecessary delays.

Warehouse personnel work with a real and up-to-date forecast, improving shift planning, inbound flows and merchandise management.

Systems such as FIELDEAS Track and Trace can help to ensure that waiting times do not exceed the limits established in regulations such as RDL 3/2022, which regulates the stoppage of loading and unloading operations.

Intelligent dock scheduling is not a trend, but an operational necessity. In an environment where margins are tight and the customer demands speed, dock management cannot be left to chance or rely on manual methods.

The FIELDEAS Track and Trace dock management module allows you to transform this critical area into a strength, generating savings, improving the carrier experience and facilitating a smooth, collaborative and connected logistics operation.

Thus, the FIELDEAS Track and Trace YMS allows you to:

In addition, the FIELDEAS Track and Trace dock management module not only provides efficiency, but also business intelligence, since it allows to analyze which time slots are the most problematic, which carriers accumulate more incidents or how to anticipate activity peaks.

09 Apr 2024

8 benefits of optimize loading and unloading dock management

19 Sep 2024

Different types of loading and unloading docks and how to optimize their management

20 May 2025

How a YMS solution with real-time technology improves dock management

19 Jun 2025

How a dock management solution improves logistics KPIs in your operations