How to improve the management of loading docks in warehouses

The management of warehouse docks and logistics platforms is a critical point in the supply chain.

The efficiency and reliability of this work depends on the chains functioning as perfect gears to place products in their destination markets in a timely manner.

However, the participation of different actors in these tasks causes frictions that, in many cases, require technological tools to grease the processes.

In addition, the various legislative changes have modified the traditional scheme for loading and unloading trucks in warehouses and logistics platforms.

In a scenario of lack of transportation supply and driver shortage, transportation plays a critical role in the chain. Keeping trucks running at peak performance and with as much cargo as possible is crucial.

Loading and unloading was a task that had been customarily assigned to drivers. However, these professionals considered that these jobs should not be their responsibility.

Since September 2022, professional drivers are prohibited from loading and unloading, except for certain exceptions.

Specifically, omitting the prohibition of loading and unloading by drivers constitutes a very serious infraction typified in the Land Transport Law (LOTT).

As a result, responsibility for these tasks now falls to the companies that manage the warehouses and logistics centers where the trucks are loaded and unloaded.

Specifically, the LOTT makes the company under whose direction the driver of the vehicle is acting, as well as the loader, shipper, intermediary and consignee involved in the transport, responsible for the infringements in the performance of loading and unloading operations.

The situation forces these companies to take control to organize the flow of goods in and out of their facilities in order to ensure that flows within the warehouses are adequate and that trucks are guaranteed to move smoothly to avoid any risk of collapse and vehicle stoppages that generate costs and logistical inefficiencies.

In this same sense, another of the main problems that exist in the management of docks and fields in warehouses and logistics platforms has to do with the waiting time that trucks are obliged to wait.

These moments mean downtime in which neither vehicles nor drivers are generating revenue and in which, in addition, delays accumulate to cover other services.

For these reasons, carriers have been demanding measures to reduce these lost times.

At the same time, waiting times also create problems for transport customers, as they generate accumulations of vehicles that clog the docks and force the management of parking spaces in the fields and, in addition, slow down the movement of assemblies at exits and entrances.

The authorities consider that stoppages have a very significant impact on the functioning of the logistics chain, so they have sought to encourage their reduction in order to reduce transport times, workers’ non-productive hours and, ultimately, costs.

Thus, the LOTT provides that when the vehicle has to wait for a period of more than one hour until loading or unloading is completed, the carrier may demand compensation from the shipper for stoppage, which will give rise to compensation.

However, this situation is of no interest either to shippers, because of the increased costs involved, or to the carriers themselves, who are focused on keeping trucks and drivers on the road for as long as possible to generate revenue.

This complex landscape is well suited for the application of technological tools that take into account multiple variables to provide solutions to complex problems and also drive collaboration in the logistics chain.

Specifically, the use of new technologies to manage loading and unloading operations at warehouse docks and logistics platforms allows:

In addition to bringing multiple benefits to the company itself, digitizing warehouse dock management brings a series of benefits to the entire supply chain and all the agents that make it up, and represents a significant improvement in other areas of the company and the sector.

Efficiency in dock management depends heavily on coordination with suppliers and carriers. Implementing advanced communication systems, such as collaborative cloud platforms, enables real-time information sharing on dock availability, estimated arrival times, and potential delays, which reduces lead times and improves planning. This collaborative approach can minimize errors and improve synchronization throughout the supply chain.

Efficient loading dock management not only affects local operations, but also has a significant impact on the global supply chain. Optimizing these processes helps reduce total product cycle time, improves responsiveness to market demand and minimizes supply chain disruptions. In addition, effective dock management can help reduce logistics costs and improve competitiveness in international markets.

Poor management of loading docks can generate significant risks for the safety and health of workers. Therefore, digitizing warehouse dock management is essential to implement preventive measures, standardize procedures, optimize spaces and have greater control of personal protective equipment (PPE).

More efficient loading dock management can contribute significantly to a company’s sustainability goals. Optimizing operations reduces truck fuel consumption by minimizing waiting times and unnecessary maneuvering, which in turn reduces greenhouse gas emissions. In addition, adopting practices such as the use of electric vehicles or the implementation of renewable energy on the docks can further enhance sustainability.

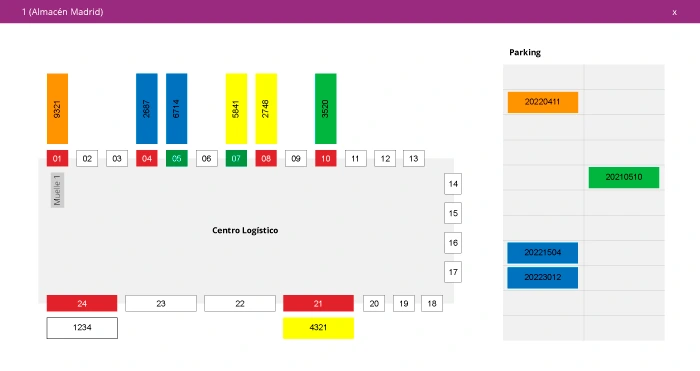

FIELDEAS has developed a specific module to manage loading docks and unloading docks in warehouses and logistics platforms within its FIELDEAS Track and Trace supply chain visibility tool.

This tool directly connects all actors in the chain in real time. This generates optimization scenarios that benefit from faster procedures, greater efficiency and a better capacity to react to any possible incident, facilitating collaboration among all the actors in the chain.

The system offers advanced capabilities including:

It is also essential to establish and monitor specific KPIs, which the FIELDEAS Track and Trace platform will extract and analyze.

On the other hand, FIELDEAS Track and Trace allows integration with ERP/WMS systems, enabling smoother coordination between warehouse operations and loading/unloading activities.

This integration facilitates real-time visibility of dock availability, shift scheduling, resource allocation and synchronization with production and distribution demand. It also helps automate processes, reduce manual errors and optimize the flow of goods.

Optimize the management of loading and unloading docks and boost the productivity of your transport operations.

11 May 2022

Slot management and route planning for advanced transport management

30 Jun 2022

FIELDEAS Track and Trace Quality and Innovation Award

07 Sep 2022

Up to date with the latest changes to the consignment note