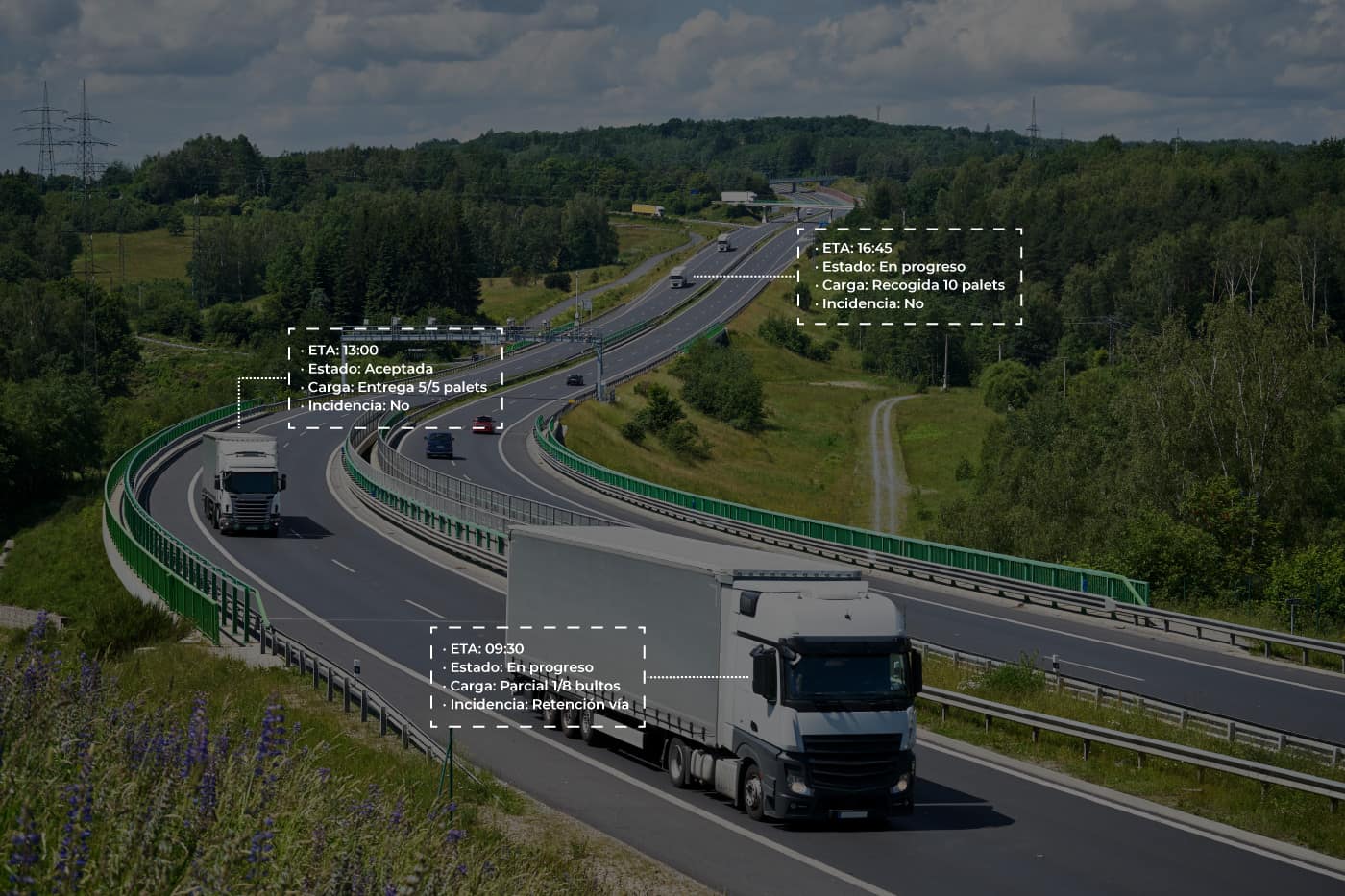

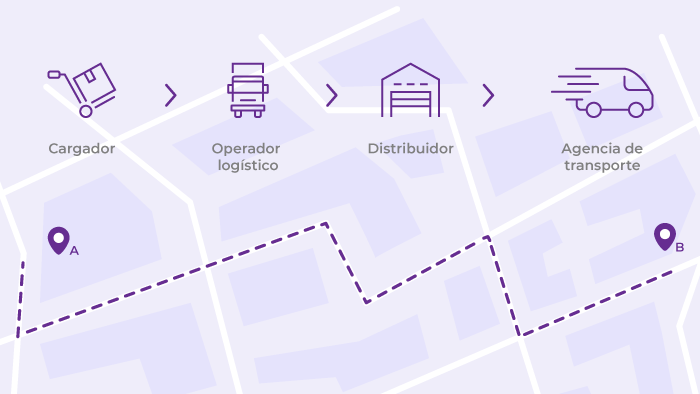

When we talk about visibility in logistics, we are talking about an indispensable term to provide agility and responsiveness in the supply chain. To achieve this, it is essential to have the right tools to help us obtain real-time data and optimize operations by monitoring key and accurate information. Improve order management and traceability, ensuring efficient and sustainable deliveries. At the same time, increasing customer satisfaction through the fulfillment of the agreed SLA’s.

Why is it important to have good end-to-end visibility?

All those who want to achieve flawless supply chain management use visibility as a means to achieve this. FIELDEAS Track and Trace provides complete visibility into the supply chain real-time traceability to anticipate all delivery movements.

Having complete visibility over the end-to-end supply chain helps:

- To have more control over the orders placed with the supplier and to know if they stored the goods on time, if the transport will be delivered on time or if the conditions for the movement of goods are met as agreed.

- Act in time to be able to solve a stock out. Inventory can be identified and varied to meet demand requirements. It helps us to better understand what the sales department may or may not promise the customer, which makes it possible to forecast increases in demand or other fluctuations in consumer habits.

- To be able to know in which areas knowledge needs to be increased, including new indicators, collecting metrics or adjusting KPIs periodically.

- Optimize traceability of goods. This minimizes risk and increases safety by guaranteeing transport in the best conditions. All of this helps customer service improve in quality and clarity, and increase on-time delivery rates.

Thanks to the ability to capture and integrate data, visibility creates intelligence based on the knowledge we acquire with the tools we work with. If we do not have this global perspective that gives us visibility, decision making would not work with enough sources to make the supply chain clear and we can take full advantage of what it does not offer.

What types of goods do you work with? FTL, LTL or STL

Within end-to-end visibility, the type of goods being handled also comes into play. Companies or shippers have a variety of options available to them depending on the size of the shipment they want to make. For example, we find FTL goods, LTL goods or STL goods. These types of goods are perfect for providing a transport solution in different situations, but it is important to know the main differences between each and when to use them.

FTL (Full Truckload) refers to fulltruckloadcargo. On the other hand, LTL or “Less than Truckload” cargo, according to its acronym, is cargo that does not fill a full truckload.

LTL typically occurs when the cargo from several shippers is included in the same truck, without having to use a dedicated load on an individual trailer. This is the perfect option for shipments involving 1 to 6 pallets, as it makes the best use of the space available for the shipment.

If we talk about STL goods, we refer to goods where a full load is required, for example, a Class 8 tractor including a van. With STL the load will be the only one transported on the truck, it is exclusive and fills the entire truck.

Get full traceability of shipments throughout the entire supply chain: End-to-end visibility for all shipments. Multimodal solution to know the status of your LFT, FLT, ocean freight or parcels in real time.

What are the differences between LTL and FTL?

The big difference we can find between these two types of shipments is that LTL offers greater cost savings when it comes to shipping multiple pallets at once. This is cheaper for the company as it is only paying for the space it really needs and not for the whole truck, which is not even full. Carriers using LTL have to maintain shipment efficiency by trying to fill underutilized space with other cargo they can find.

Another key difference between LTL and FTL is related to managing traffic. With a full truck, the driver will pick up everything he is shipping and take it directly to the receiver, making transit seamless. Considering that the driver will not encounter any problems on the trip, the goods will arrive at the right time and with the appropriate mileage.

On the other hand, LTL transittypically uses a more complicated route with more stops to pick up goods, so delivery dates given are an estimate and not a guarantee.

There are no specific and obligatory rules to follow regarding the use of LTL or FTL, each moment and each merchandise will require one or the other, although there are some situations where full truckload transport may be the most appropriate.

Whatever the type of your goods, end-to-end visibility of your shipments is essential. FIELDEAS Track and Trace is theperfect multimodal solution for complete management and control from origin to final delivery.

+INFO: Get end-to-end visibility with FIELDEAS Trace and Trace