Management by exception in the management of loading and unloading docks, is it feasible?

Loading dock management is one of the most critical points in logistics operations.

The lack of coordination between actors, availability of resources and space occupancy generates delays, downtime, congestion and a poor experience for carriers, operators and shippers.

In this context, technological solutions for slot planning and control open the door to a new operational approach: automating the usual processes and dedicating resources only to the incidents that require it.

This model is known as management by exception, and represents a radical change in terms of efficiency and control in the management of loading docks.

In traditional operations, teams are constantly monitoring every step of loading dock management: arrivals, dock assignments, unloading times and resource coordination. This is a high workload, even when everything is running smoothly. Management by exception reverses this workflow.

Thanks to dock management or YMS solutions such as FIELDEAS Track and Trace, the most routine tasks are planned and executed in an automated way.Thanks to dock management or YMS solutions such as FIELDEAS Track and Trace, the most routine tasks are planned and executed in an automated way. When the system detects deviations, such as delays, changes in the order of arrival, problems with documentation or busy docks, it automatically raises them as alerts.

In this way, the team concentrates exclusively on resolving real incidents, focusing its work on performing real value-added tasks.

This model not only improves efficiency, but also reduces operational pressure, minimizes human error and allows problems to be anticipated rather than reacted to.

The implementation of specific solutions for slot management is what makes it possible to manage loading and unloading docks by exception.

These solutions act as intelligent control centers that automate planning, monitor execution and facilitate collaboration among all stakeholders.

Among the most outstanding functionalities of a dock management module such as FIELDEAS Track and Trace, the following stand out:

This functionality allows for the advance planning of time slots, with configurable rules by type of merchandise, supplier, priority…

The logistics manager maintains full control over the planning, being able to approve, reject or modify appointments according to operational needs.

In addition, the platform supports dock blocking for internal uses and provides real-time visibility of staff availability. All this contributes to a dynamic, efficient operation that is aligned with the actual capacity of the logistics center.

Integration with a visibility and traceability solution such as Track and Trace makes it possible to accurately calculate the ETA of each truck, anticipating possible overruns or delays.

This information is connected in real time with dock management, allowing proactive action to be taken in the event of deviations. The system issues automatic alerts to all parties involved to avoid operational conflicts.

In addition, it offers visibility of staff availability, facilitating a management adjusted to the reality of the center. The entire process is based on traceability and anticipation.

The management by exception that is achieved with YMS solutions also materializes in access control.

The FIELDEAS Track and Trace dock management module improves access control to logistics platforms, increasing security and efficiency in vehicle entry.

Security personnel can look up key data such as license plate and driver in advance to verify authorizations.

In addition, it integrates with physical devices such as license plate readers and automatic barriers to automate access. It also connects with CAE systems to validate driver requirements, streamlining the process and avoiding operational blockages.

Another highlight of the management by exception derived from the implementation of YMS solutions such as FIELDEAS Track and Trace is the layout or platform manager.

This functionality provides a clear and real-time visualization of the logistics yard, since it allows the exact position of each truck within the enclosure to be located on an interactive map, which greatly facilitates the monitoring of the operation in a simple way and without having to stop performing other valuable tasks.

One of the main logistical challenges is the lack of visibility in inbound processes, which makes resource planning difficult. To solve this, our solution incorporates an Inbound Planner that organizes and coordinates the reception of raw materials from the source.

Suppliers provide information on quantities, dates and delivery times, adapting to the needs of the logistics center. This allows the shipper to anticipate, allocate resources and optimize the use of space. The result is more efficient planning without uncertainty.

In this way, we have seen how technology not only improves the execution of loading dock management, but also transforms the operating model, facilitating more strategic, efficient and focused supervision.

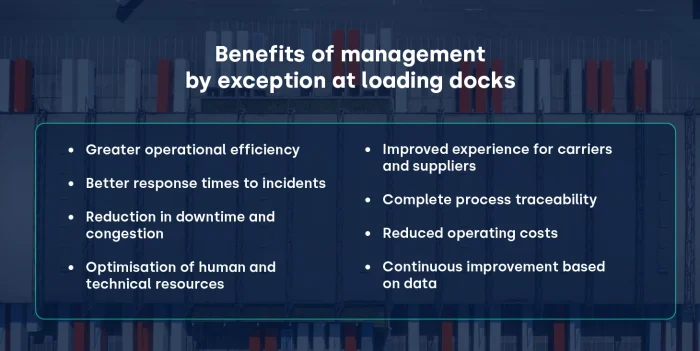

Driving management by exception within loading dock management brings clear competitive advantages for shippers and thus for carriers.

Standard process automation frees personnel from repetitive tasks and allows them to focus on solving real problems, optimizing the use of resources.

By detecting deviations in real time, quick and effective decisions can be made to minimize the impact of delays or conflicts at the docks.

Digital scheduling combined with automated control avoids queues, unnecessary waiting and overlapping appointments.

The equipment can be sized according to the actual demand, as it is not necessary to have dedicated personnel to control each movement, only exceptions.

Smoother processes, shorter lead times and better coordination increase the satisfaction of everyone involved in the supply chain.

Every action, alert or intervention is recorded in the system, allowing the entire logistics flow to be accurately tracked and audited.

Less administrative burden, fewer errors, efficient use of space and human resources translate directly into economic savings.

The information gathered allows us to analyze patterns, identify bottlenecks and redesign processes for more efficient and sustainable loading dock management.

Loading dock management has ceased to be a purely operational task and has become a strategic axis of efficiency and control within the logistics chain.

Thanks to technology and an approach based on management by exception, it is possible to automate the routine and focus human effort where it really adds value.

19 Jun 2025

How a dock management solution improves logistics KPIs in your operations

20 May 2025

How a YMS solution with real-time technology improves dock management

29 Apr 2025

How to eliminate blind spots in your inbound logistics with a YMS system

10 Apr 2025

The comprehensive solution for managing all types of loading docks