On Thursday, February 8, the first in a series of three webinars organized by FIELDEAS Track and Trace on visibility and control for supply chains in motion was held on dock management.

In this post we will talk about

show

This first meeting focused on the optimization of dock management in a collaborative way, where Rodrigo Martín, Transport and Logistics Manager at FIELDEAS, and Alfonso Martín, Presales Manager at FIELDEAS, analyzed the main advantages of using a tool such as FIELDEAS Track and Trace for this purpose.

As explained by our experts, dock optimization is important because it allows to reduce waiting timesAt a time when regulations have reduced the maximum waiting time for a carrier at the loading or unloading platform to one hour; increase productivityThe efficient dock allows a higher volume of cargo to be handled in less time; reducing costs; and, as a result, improving customer satisfactionwhich, in turn, strengthens your company’s competitiveness.

The optimization of the management of loading and unloading docks results in the following reduce lead times by 30%, which means a 15% increase in order processing capacity for the shipper and a 20% improvement in the timeliness of deliveries to end customers.

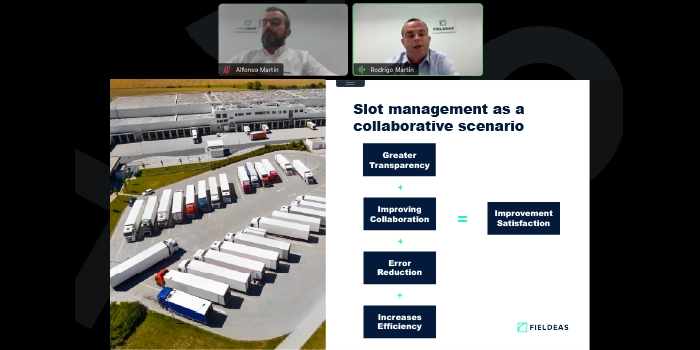

Slot management as a collaborative scenario

If there is one key element in the proper management of the docks, it is collaboration. As reflected during the first webinar on visibility and control for supply chains in motion of FIELDEAS Track and Trace, the tracking and tracing tool for the supply chain. should enable all employees to can make dock reservation requests, access data or report delays or changes, allowing you to allocate and move your logistics center planning in a structured way.

Thus, in order to carry out good management, it is essential to involve each of the stakeholders, so that all participants in the process have all the information available to them in real time.

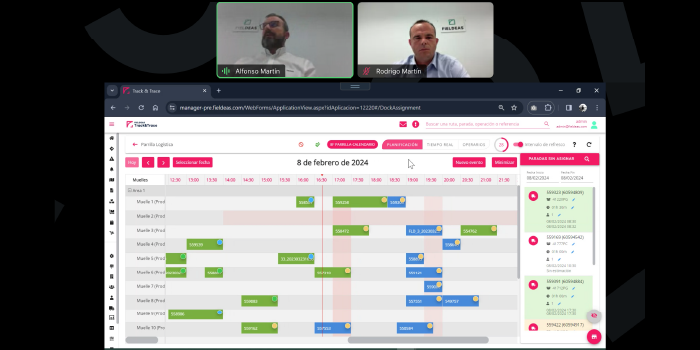

The webinar on optimizing dock management in a collaborative way showed that a correct dock management is directly related to the prediction of possible present and future incidents. The Track and Trace tool allows real-time processing of information, which facilitates proactive decision making and replanning of dock reservations before problems materialize.

Management and monitoring of logistics center capacity

Anticipating demand and resource availability is essential for proper dock management. To do this, it is important to have complete visibility of all shipments in order to perform predictive analysis and, ultimately, to be able to plan flexibly, advantages that only a Track and Trace tool such as FIELDEAS can provide.

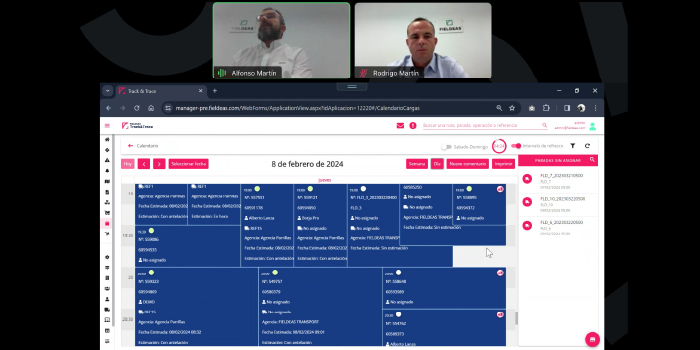

Control of stoppages and arrival at the plant

It is important to have a collaborative model in dock management and to integrate carriers as a key player, because this eliminates disputes between warehouse personnel and drivers, resulting in increased operational capacity.

The platform’s flexibility also allows you to easily manage your own and subcontracted fleets, various logistics facilities with different characteristics, and even take into account complex logistics activities such as cross-docking, where any modification generates a chain of alterations that can worsen the service offered to the end customer.

How FIELDEAS Track and Trace helps you with spring management

Everything that was presented during the webinar has a practical application in the real environment thanks to the FIELDEAS Track and Trace technology, a tower control that allows visibility of all transportation processes regardless of the model (FTL, LTL, cross-docking, last mile…) and the mode of transport (road, rail, maritime…), since it responds to a collaborative model.

Thus, with this Supply Chain Visibility, from a single platform all the agents involved in the supply chain, from shippers, logistics operators to the carrier itself, even giving visibility to the end customer, can access all relevant data within the management of the entire supply chain, where the optimization of dock management is a key element.

Two new webinars coming soon

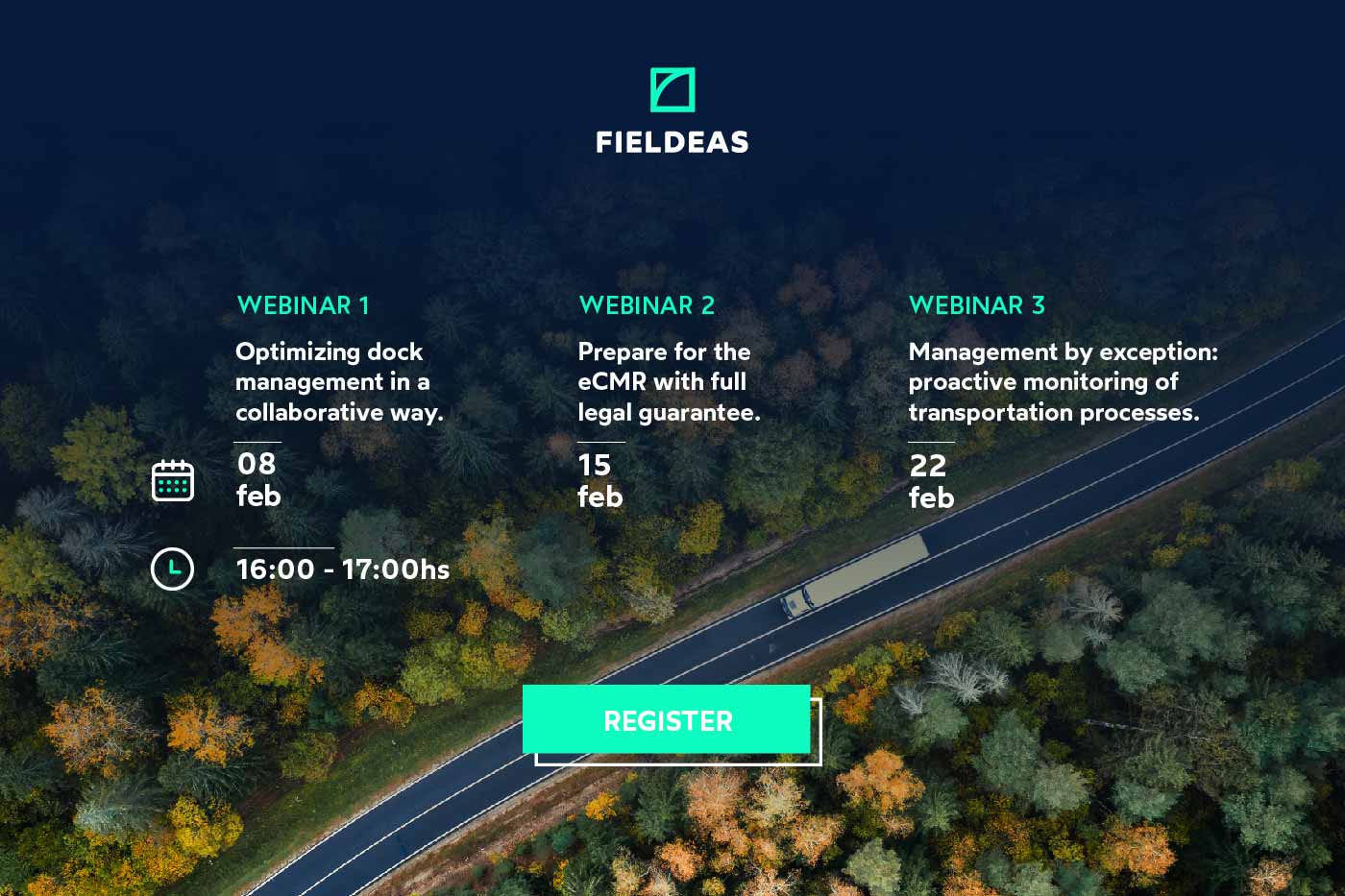

FIELDEAS plans to hold two new webinars this February to analyze practical keys for companies to get the most out of the digital transformation process in the logistics and transport sector.

So the second webinar will be held on Thursday, February 15 at 4 p.m., with the title Get ready for the eCMR with full legal guarantees.

The meeting will focus on the benefits that eCMR brings to all actors in the supply chain, from the reduction in the use of paper, to improvements in invoicing.

In particular, the legal security provided by the FIELDEAS eCMR by incorporating electronic signatures will be analyzed.

On the other hand, the last session of these three webinars will take place on Thursday, February 22 at 4 p.m., with the title Management by exception: proactive monitoring of transport processes.

This virtual meeting will focus on the advantages provided by the digitization of transport through the analysis of real-time data to generate alerts and automatic notifications that allow taking measures in the event of unexpected events or critical situations, to proactively manage transport operations, improve the treatment of service incidents and improve customer service.