The third and last webinar of the series “Visibility and control for supply chains in motion” organized by FIELDEAS Track and Trace under the name “Management by exception: proactive monitoring of transport processes” took place on Thursday, February 22nd.

In this post we will talk about

show

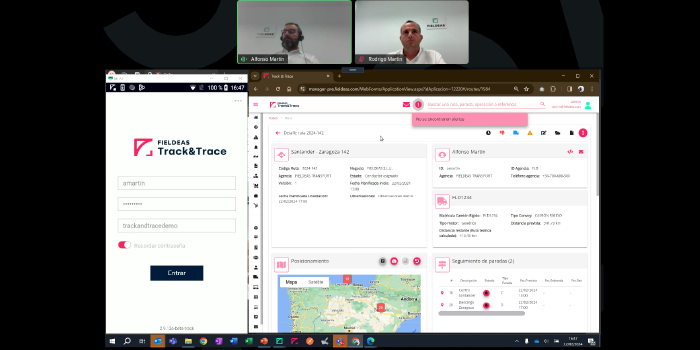

With the explanation of our experts Rodrigo Martín, Transport and Logistics Manager of FIELDEAS; and Alfonso Martín, Presales Manager, we were able to see how management by exception is achieved in transport processes and what are its main benefits.

Objectives and results of management by exception in transport

Before analyzing how to achieve management by exception in transportation, it is important to be clear about the objectives and, therefore, the main results obtained from proactive monitoring of the transportation process, which can be achieved with solutions such as FIELDEAS Track and Trace.

- Resource optimization within transportation operations. We do not have more resources than necessary.

- Efficient organization with the assignment of incidents to the correct teams.

- Improved service quality. We anticipate supply chain disruptions and apply solutions before it becomes a problem at the end customer.

- Increased management efficiency.

- We avoid non-compliance and guarantee the SLA. We anticipate so that there are no non-compliances.

- Customer satisfaction. We comply with the ETA, which increases confidence.

How to achieve management by exception in transport

Management by exception in transportation is a medium to long-term process in which we will improve all the processes we carry out by applying technology whenever possible.

To do this, the first thing to do is to analyze the feasibility of incorporating technology in each part of the transportation process, bearing in mind that the investment-benefit ratio must always be measured.

By incorporating as much technology as possible, flexibility is gained and much less costly and much more efficient and sustainable results are obtained.

In order to carry out management by exception in the process of digitization of transport, it is very important to be clear about the phases to be addressed in an operation. In this way, we propose five distinct phases:

1. Supervision

We must have the ability to supervise the operation. As our experts explained, monitoring does not mean reviewing all the information, but only what is necessary.

To do this, we must configure at the parameter level everything we want and need to supervise in the process so that the system is able to provide us, automatically, with everything that is happening in this daily operation within the entire supply chain.

2. Detection

In the second phase, to achieve management by exception, we must be able to detect any discrepancies in the process.

Thanks to a solution such as FIELDEAS Track and Trace we can configure those anomalies of which the system must alert us so that we can focus on them, act and apply a solution.

3. Management

In the management phase we must act, if necessary, to provide a solution to the possible alert or anomaly that has been detected.

This is the first stage in which there is human intervention and the objective is to be as limited as possible and focused on a specific action, in order to mitigate the problem.

4. Solution

In the last stage, we will look for a solution to the problem based on an environment with all the information available in real time.

This allows us to evaluate the anomalies or incidents that have been detected and, in addition, to evaluate the different inputs to find a solution to the detected alert.

5. Learning

In addition to solving anomalies, we must be able to materialize a learning phase, to be able to apply as starting points the monitoring and detection of these discrepancies based on what we have learned or even apply a solution that over time we will be able to standardize to a specific problem.

This will allow us to learn from the system and be able to establish new concrete processes and standardize or update a process that we had already detected.

Real-time data mining for proactive monitoring

To carry out these phases, we must carry out real-time data mining through different sources of information.

- Telematics. Possibility of incorporating the information of the digital tachograph and of the geopositioning embarked. With this we get a good calculation of the ETA.

- Sensorics & iOT. If the business requires it (such as pharma or food) we have the possibility of incorporating temperature devices, cold machine sensors or door opening sensors, among others.

- Operational data. The driver can report events performed, actions linked to those events and confirmation of operations.

APPS. By applying technology on the driver’s side, we allow the driver to incorporate different elements that will improve operations, such as scanning documentation to be able to carry it in 100% digital format, such as the eCMR. It can also report incidents and include the advanced digital signature.

- Integrated systems. The FIELDEAS Track and Trace solution can be integrated with different systems, such as access control or weighing.

How to classify unattended notifications

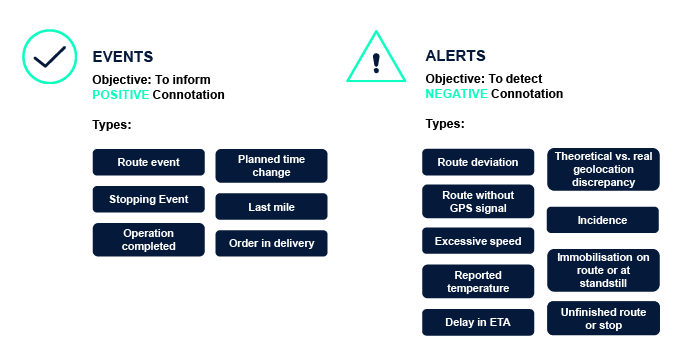

Once we have seen how we can rely on technology to achieve management by exception in transportation processes, it is important to classify the notifications that the system will send us automatically. FIELDEAS Track and Trace makes two classifications:

- Events. The objective is to inform internally or externally of something that has happened (route event, stop event, operation completed, change in planned time…). Its connotation is positive and it is only about automating the information message.

- Alerts. The objective is to detect an anomaly and, therefore, the connotation is negative. An alert requires the intervention of a work team (route deviation, route without GPS signal, delay in ETA, reported temperature, immobilization…).

After knowing the catalog of events and alerts we must see how we treat them. To determine the events and alerts we must know what we want to notify, how we want the system to notify us, and who we want to notify.

Incident management

Once we have configured the alerts, we move on to the incident management module. An incident can be generated automatically or manually by the driver and we propose three phases for its treatment:

- New incident DETECTED. It is registered in the system with all the available information, both its own and related. The 360º information allows to assign its management to one team or another.

- Incident in TREATMENT. When it has already been assigned, the system facilitates its management.

- RESOLVED incident. When the equipment has resolved it, the system reports it. If it has not been resolved, it is catalogued as a discarded incident so that there will never be active incidents in the process.

Conclusions on management by exception in transport

In summary, management by exception in transportation, in addition to providing economic benefits by optimizing resources, offers proactive prediction, which, in turn, allows flexibility when it comes to acting in the face of possible incidents.

Moreover, having real-time information from different sources allows for a better analysis of the problem and an improvement in the decision-making process to apply the necessary solutions.

In this sense, the FIELDEAS Track and Trace solution, as reflected during the demo during the webinar, allows you to configure the different events and alerts, and determine how we want to be notified and to whom. It is a solution that adjusts to the needs of each business and provides information in real time in order to optimize transport operations.

If you want to optimize your operations and focus only on what is really important, gaining efficiency and flexibility, trust the FIELDEAS Track and Trace solution.